- Minimum clearance required is 22-24 inch (24 inch being optimal)

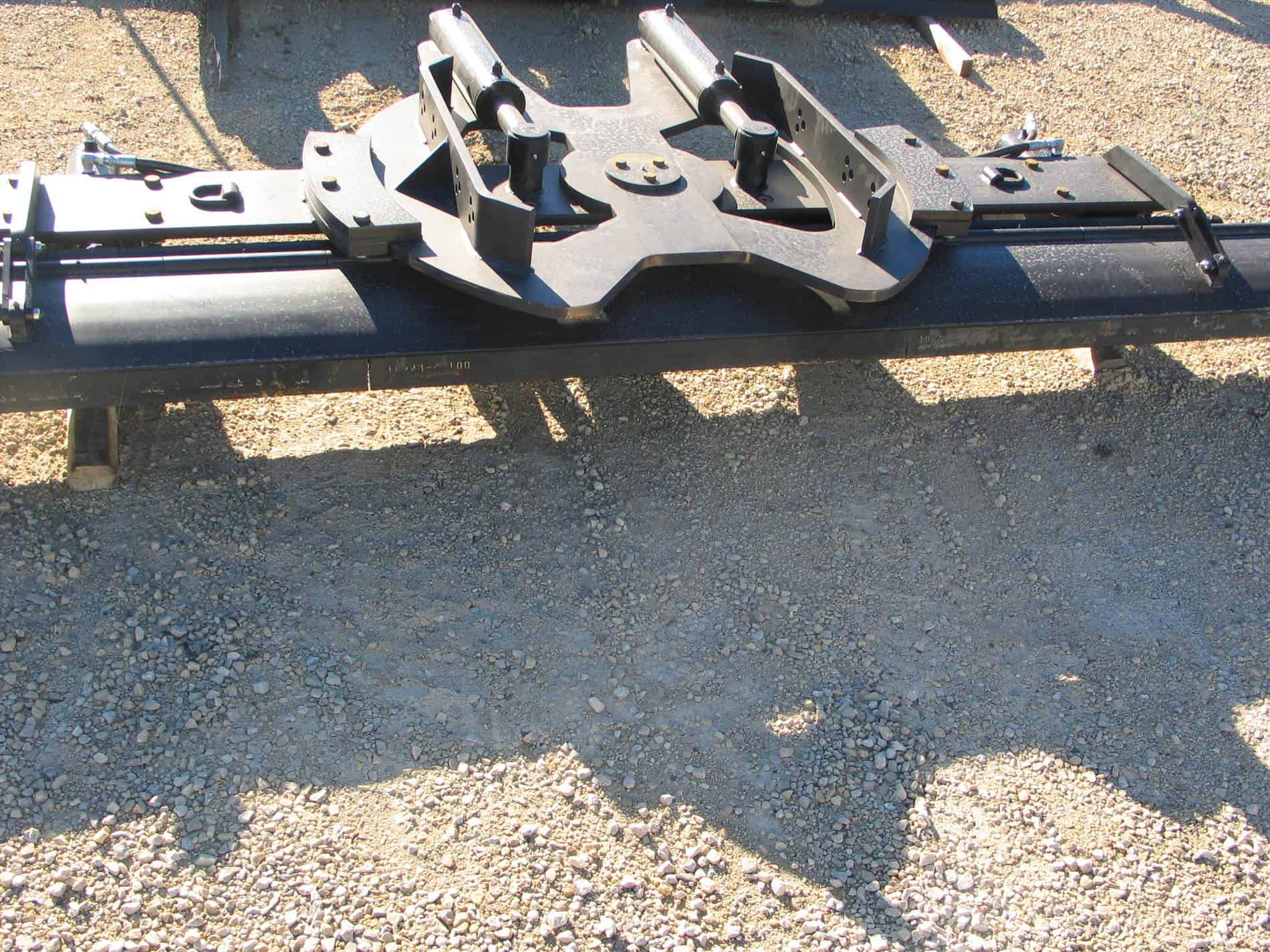

- 11 ft. & 12ft. scraper lengths

- Scraper shall be extra heavy duty for year round use

- Truck mount hanger plates are 3/4″ thick

- Shim adjustable mounting height incorporated into side plate

- Heavy duty 1″ solid circle with one piece design and reverse cylinder hold down

- Two (2) 4″ x 14 1/4″ swing cylinders with 2″ Nitrided Rods (able to swing 45 degrees left or right)

- Reverse cylinder mounting pins are 2″ diameter

- Reverse cylinder pins have removable top washers to aid in the ease of service

- 1″ thick hold down blocks with three 3/4″ grade 8 bolts

- Replaceable 3/8″ UHMW Polyurethane hold down wear pads (between the hold down blocks and the reversing circle)

- 1″ x 10″ hanger board with reinforced center

- Machined 5″ center pivot pin with replaceable bushing

- Four (4) heavy duty long travel spring assemblies with 3/4″ diameter wire and reinforced ends

- Two (2) heavy duty 4″ actuating cylinders with 2″ Nitrided piston rods

- The actuating cylinders will be mounted with 1 1/2″ pivot pins

- ALL MOLDBOARD PIVOT POINTS ARE GREASEABLE

- Heavy duty upper moldboard pivots are greaseable and have replaceable brass bushing

- 1″ x 12′ upper moldboard pin

- Two piece moldboard shall be 1/2″ x 10″ upper and 3/4″ x 9″ lower x 12′ in length, middle board is 1/2″ x 6″ x 12′

- 1 1/2″ x 110 1/2″ middle moldboard pin

- Standard 1/2″ x 6″ cutting edge with standard hole punch (pre-punched for future carbides)

- The cylinders will provide a hydraulic lock for holding the moldboard in place while in use

- Primed and painted standard black

- One year warranty

- Scraper cushion valve, to protect reversing cylinders

- 7/8″ x 5″ carbide cutting edge ilo standard 1/2″ x 6″

- Orange end option

Social